+86-755-2301-3143

Coating | Cutting | Slitting | Rewinding | Die-cutting

Anti-static Copper Foil Tape is a special kind of tape with many characteristics and wide application areas, the following is a detailed introduction about it:

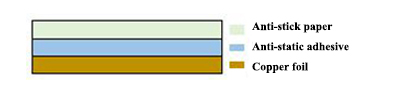

Structure and material:

Anti-static copper foil tape is made of a thin layer of copper foil with an anti-static adhesive coating on the other side. It is a kind of tape used for the anti-static protection of electronic equipment and components.

We are a one-stop ESD tape provider from China. We offer coating, slitting, and die-cutting, as well as jumbo rolls, small rolls, and die-cuts to meet ESD tape requirements. If you are looking for ESD tape, we are ready to help your business.