+86-755-2301-3143

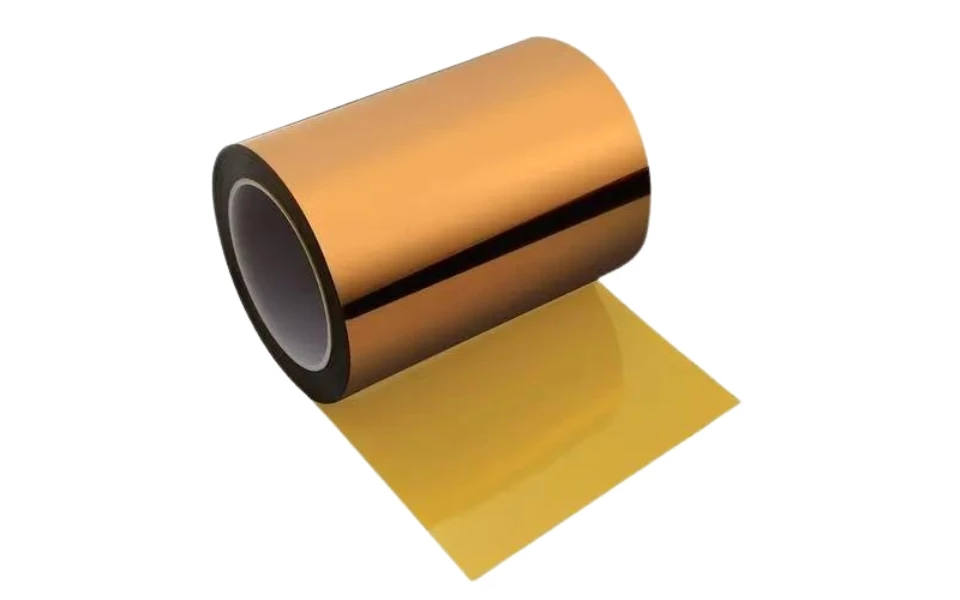

Coating | Cutting | Slitting | Rewinding | Die-cutting

Short Answer: Standard Kapton tape is not ESD-safe due to its insulating properties. However, it can be modified to meet ESD safety requirements through specialized treatments.

Material Properties:

ESD Risks:

To achieve ESD compliance, Kapton tape can be engineered using these methods:

[Contact us] for samples, technical support, or a quote tailored to your project’s needs.

If you have any questions, please contact us via email, phone, or WhatsApp. Our professional team will give you the answers you want!

We are a one-stop ESD tape provider from China. We offer coating, slitting, and die-cutting, as well as jumbo rolls, small rolls, and die-cuts to meet ESD tape requirements. If you are looking for ESD tape, we are ready to help your business.