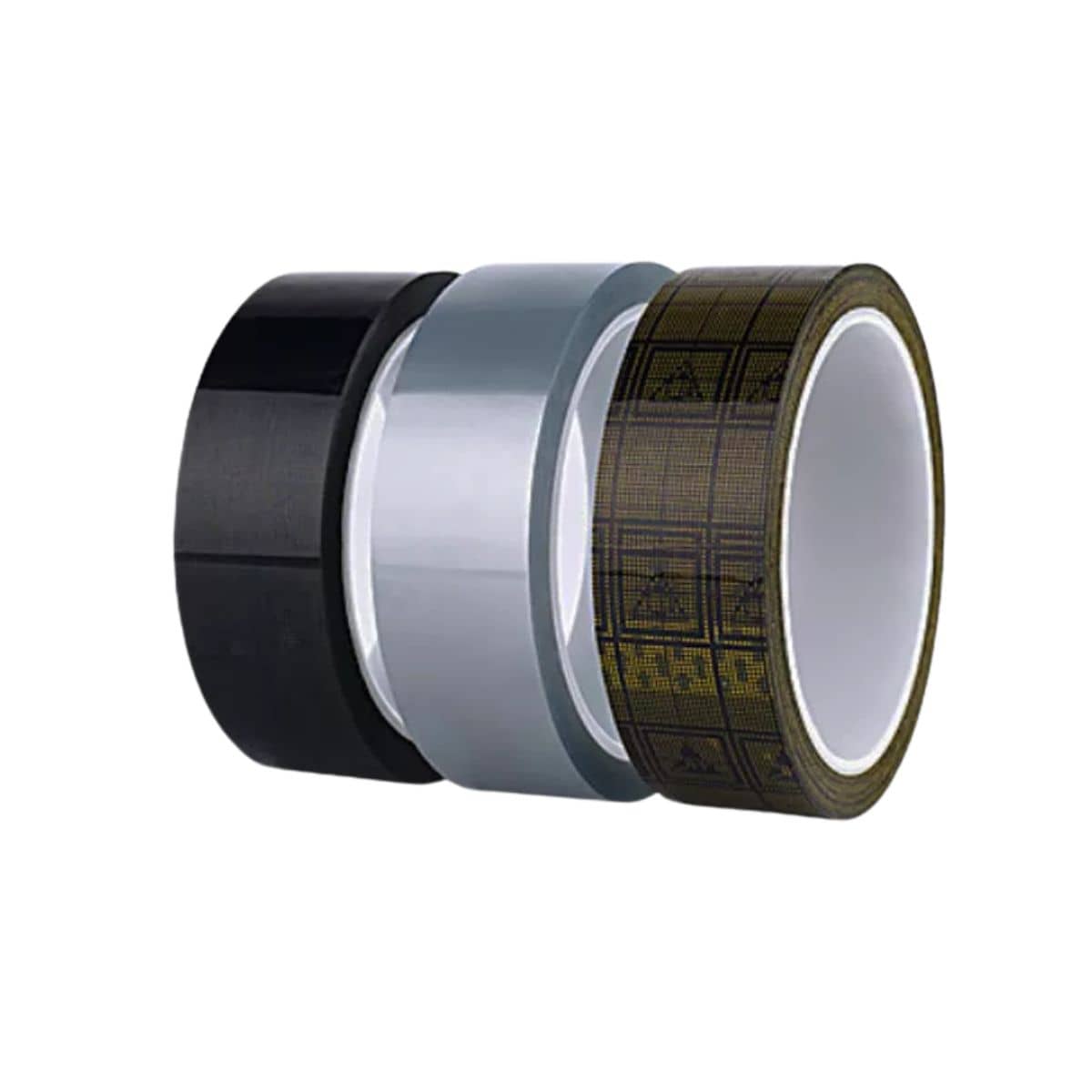

Static dissipative tapes are special types of tapes that have the ability to dissipate static charges quickly, preventing the build-up of static electricity and thus protecting sensitive electronic equipment, products or the environment from electrostatic discharges (ESD). The principle of operation is based on the addition of special conductive or static dissipative materials to the tape. These materials usually have a certain degree of conductivity, can make the electrostatic charge in the tape surface or inside the formation of conductive channels, so that the electrostatic charge will be guided to the ground or other grounded objects, to achieve the rapid dissipation of static electricity.

According to the substrate: common polyester (PET) substrate, polyimide (PI) substrate, polypropylene (PP) substrate and so on. Different substrates have different physical and chemical properties and can be selected according to specific needs. For example, PET-based adhesive tapes have better transparency and mechanical strength, and are suitable for general packaging and surface protection of electronic devices; PI-based adhesive tapes have higher high-temperature resistance, and are commonly used in aerospace, high-end electronics manufacturing and other environmentally demanding fields.

According to the adhesive type: mainly acrylic adhesive, silicone, rubber adhesive and so on. Acrylic adhesive has good adhesion and weather resistance, applicable to most conventional environments; silicone has excellent high and low temperature resistance and chemical stability, commonly used in some of the higher performance requirements of special occasions; rubber adhesive adhesion, the adhesion of some rough surfaces is better, but the weather resistance is relatively poor.

If you have any questions, please contact us via email, phone, or WhatsApp. Our professional team will give you the answers you want!

We are a one-stop ESD tape provider from China. We offer coating, slitting, and die-cutting, as well as jumbo rolls, small rolls, and die-cuts to meet ESD tape requirements. If you are looking for ESD tape, we are ready to help your business.